Post History

A few months ago, I too was looking for answers on how to connect the USB shield with ESD in mind. I always connect the shield through a resistor to ground and a capacitor to ground (100kΩ and 0.0...

#2: Post edited

- A few months ago, I too was looking for answers on how to connect the USB shield with ESD in mind.

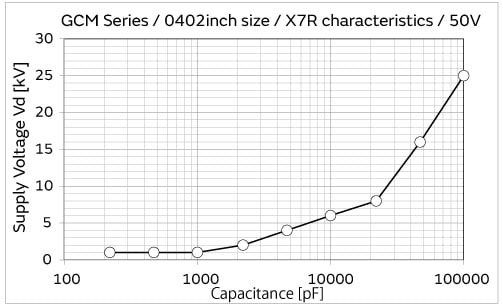

- I always connect the shield through a resistor to ground and a capacitor to ground (100kΩ and 0.01uF). Pulsing ESD into the shield is a part of the test. The ESD will appear across the capacitor, so it has to absorb the ESD pulse and survive. Can a reasonably sized ceramic capacitor survive? This article: [Ceramic capacitors for ESD Protection in Automotive Applications (Vishay, 2020)][1] mentions that an automotive grade ceramic capacitor 0.01uF, rated for 200V, in 0805 package can survive ESD pulses. The article details to what level per IEC 61000-4-2.

- > Because the shield is tied to PCB GND, [...]

- Is your USB shield tied directly to PCB ground? The shield shouldn't be connected directly to ground on the device side. The shield should be directly connected on one end (either end). The other end should be floating, or AC-coupled to GND, but not directly connected to GND. A typical USB host (laptop, hub, wall wart charger) has the direct connection between shield and its ground[^1]. Thus, the host end is that one end where the shield is directly connected.

- [^1]: Such design choice is forced on us device designers. We aren't in control of the host hardware.

[1]: https://passive-components.eu/mlccs-for-electrostatic-discharge-esd-protection-in-automotive-applications-vishay-white-paper/

- A few months ago, I too was looking for answers on how to connect the USB shield with ESD in mind.

- I always connect the shield through a resistor to ground and a capacitor to ground (100kΩ and 0.01uF). Pulsing ESD into the shield is a part of the test. The ESD will appear across the capacitor, so it has to absorb the ESD pulse and survive. Can a reasonably sized ceramic capacitor survive? This article: [Ceramic capacitors for ESD Protection in Automotive Applications (Vishay, 2020)][1] mentions that an automotive grade ceramic capacitor 0.01uF, rated for 200V, in 0805 package can survive ESD pulses. The article details to what level per IEC 61000-4-2.

- > Because the shield is tied to PCB GND, [...]

- Is your USB shield tied directly to PCB ground? The shield shouldn't be connected directly to ground on the device side. The shield should be directly connected on one end (either end). The other end should be floating, or AC-coupled to GND, but not directly connected to GND. A typical USB host (laptop, hub, wall wart charger) has the direct connection between shield and its ground[^1]. Thus, the host end is that one end where the shield is directly connected.

- [^1]: Such design choice is forced on us device designers. We aren't in control of the host hardware.

- **edit:** Article by Murata - [ESD survivability of capacitors][2].

-

- [1]: https://passive-components.eu/mlccs-for-electrostatic-discharge-esd-protection-in-automotive-applications-vishay-white-paper/

- [2]: https://article.murata.com/en-us/article/esd-resistance-of-capacitors

#1: Initial revision

A few months ago, I too was looking for answers on how to connect the USB shield with ESD in mind. I always connect the shield through a resistor to ground and a capacitor to ground (100kΩ and 0.01uF). Pulsing ESD into the shield is a part of the test. The ESD will appear across the capacitor, so it has to absorb the ESD pulse and survive. Can a reasonably sized ceramic capacitor survive? This article: [Ceramic capacitors for ESD Protection in Automotive Applications (Vishay, 2020)][1] mentions that an automotive grade ceramic capacitor 0.01uF, rated for 200V, in 0805 package can survive ESD pulses. The article details to what level per IEC 61000-4-2. > Because the shield is tied to PCB GND, [...] Is your USB shield tied directly to PCB ground? The shield shouldn't be connected directly to ground on the device side. The shield should be directly connected on one end (either end). The other end should be floating, or AC-coupled to GND, but not directly connected to GND. A typical USB host (laptop, hub, wall wart charger) has the direct connection between shield and its ground[^1]. Thus, the host end is that one end where the shield is directly connected. [^1]: Such design choice is forced on us device designers. We aren't in control of the host hardware. [1]: https://passive-components.eu/mlccs-for-electrostatic-discharge-esd-protection-in-automotive-applications-vishay-white-paper/