Post History

I'm looking for input from anyone with insight in the PLC world. How do PLCs usually measure 4-20mA current loops? I would assume it's one of these two alternatives: Through an external "shunt"...

#1: Initial revision

How do PLCs normally measure 4-20mA current loops?

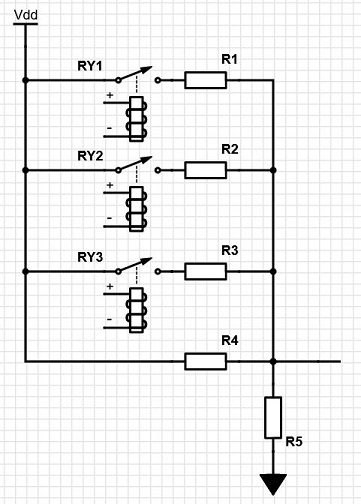

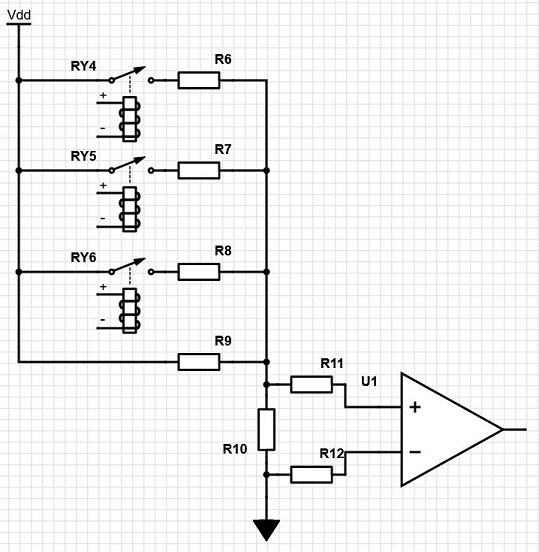

I'm looking for input from anyone with insight in the PLC world. How do PLCs usually measure 4-20mA current loops? I would assume it's one of these two alternatives: - Through an external "shunt" resistor - Through internal current sense electronics My scenario is an industrial system where I'm looking to generate different fixed current levels in a 4-20mA current loop based on relays. The fixed current will increase depending on how many relays that are active, such as no relays = 4mA, first relay = 8mA, first 2 relays = 12mA and so on. The circuit will either look like this:  That is: current is measured across a "shunt" resistor of typically 250R added externally. --- Or alternatively:  That is: R10 has very low resistance and some manner of current sense electronics are built-in inside the PLC. --- In case the PLC uses the former "shunt" resistor method, then I will have to adapt my resistor values accordingly. But in case they measure over some internal low ohm resistor like in the second picture, then I don't need to consider that. I'm looking to create a solution that will suit most PLC solutions out there, but I don't know which one of these two circuits that are the most common.