Post History

RG58 cables come in different variations, even with Teflon dielectric suitable for 200°C operations. Your cable, being suitable for up to 80°C, seems to be one of those with a PVC jacket and Polyet...

#1: Initial revision

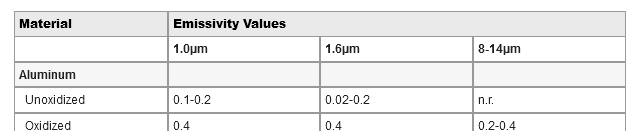

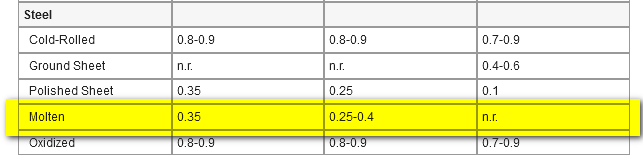

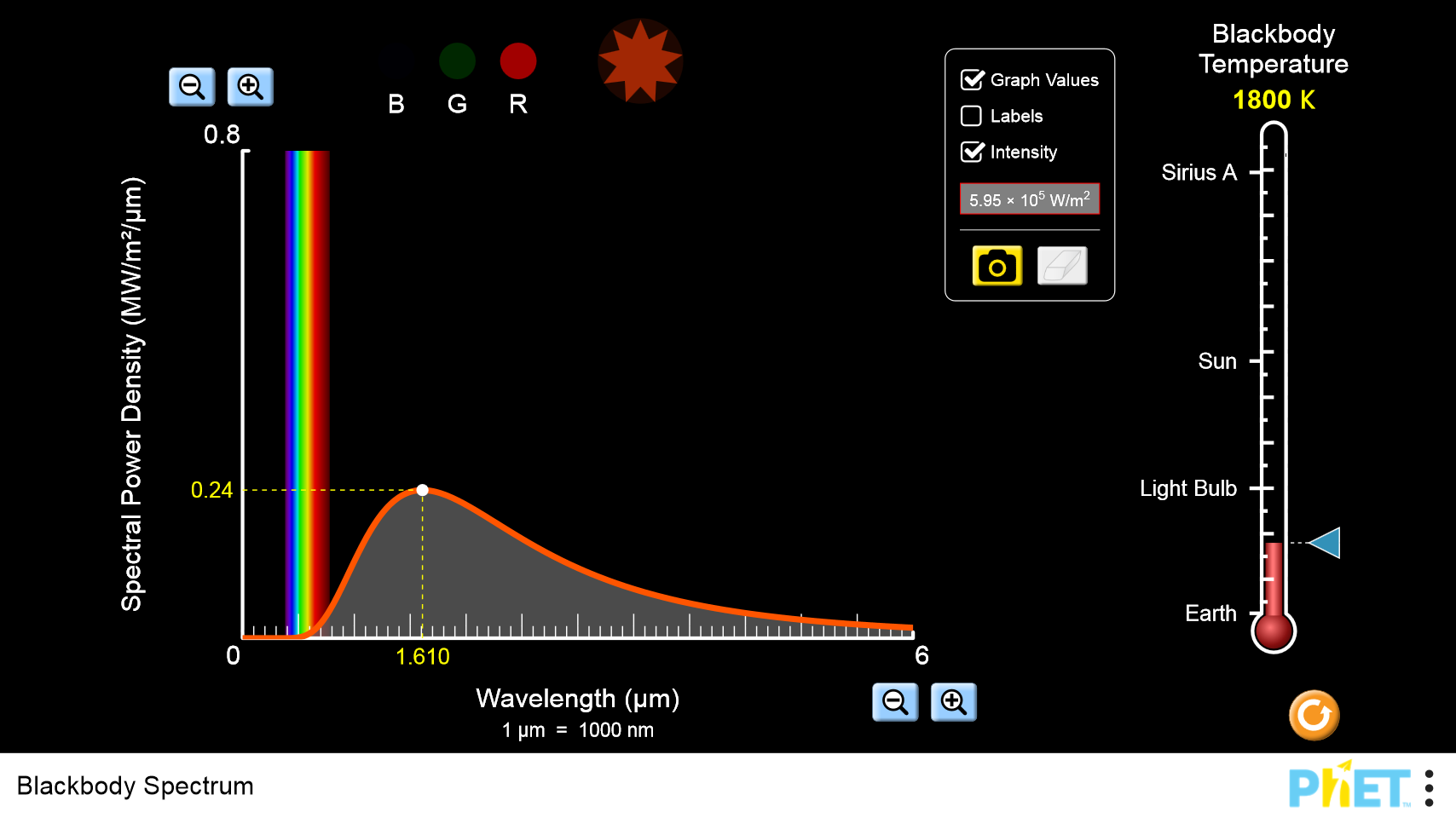

RG58 cables come in different variations, even with Teflon dielectric suitable for 200°C operations. Your cable, being suitable for up to 80°C, seems to be one of those with a PVC jacket and Polyethylene inner insulator, like [this](https://www.pasternack.com/images/ProductPDF/RG58C-U.pdf). It's bad news for several reasons, and Olin explained a few. I'll add that a problem you could have is not only the measured environmental temperature, but also **radiated heat from molten steel**. In fact steel fusion temperature is at least 1300°C and can reach over 1500°C, depending on the alloy composition. During melting and processing it can go well over that temperature. In that state the metal emits like a black body with an [emissivity of about 0.4](https://www.flukeprocessinstruments.com/en-us/service-and-support/knowledge-center/infrared-technology/emissivity-metals): <br> > > >... > > <br> and its black-body radiation spectrum has a peak in near infrared around 1.6μm according to online calculators, for a temperature of around 1800K (~1500°C). For example from [here](https://phet.colorado.edu/sims/html/blackbody-spectrum/latest/blackbody-spectrum_en.html): <br>  <br> Note that tiny number termed "intensity" (its precise name is *radiant emittance*): $5.6 \cdot 10^5 \; W/m^2 = 560 \; kW/m^2$ Multiply that by the surface emissivity of 0.4 gives about 230kW/m^2 of radiant power emitted by that surface!!! It decreases as the square of the distance and you must multiply it by the "receiving" surface dimensions, but at (say) 10m it's still a hell of a lot of power. You can literally roast some meat with that! So, if the cable is installed in line-of-sight of the molten steel surface, it can absorb a great deal of IR radiation that can heat it well beyond the measured ambient temperature (especially if its jacket is black, as it usually is). Even before you get heat damage, you can have all kinds of deformations that can vary depending on the crane position and the way that the molten steel surface "illuminates" the cable. A simple experiment to see if the radiated heat can be the cause of your problem is to wrap the cable with common aluminium [^1] foil. That would reflect quite a lot of the incoming radiated power. If you measure any difference in the comm-link quality, then you will have an important clue. [^1]: no, I won't say *aluminum*! :-)