Post History

Those are fiber optic cables that are wound back and forth between those "snowshoe" devices, which are used to limit the bend radius of the fiber. Those are needed to avoid propagation losses due ...

#3: Post edited

- Those are fiber optic cables that are wound back and forth between those "snowshoe" devices, which are used to limit the bend radius of the fiber.

- Those are needed to avoid propagation losses due to the fiber being bent more than its rated maximum bend radius.

- The fiber must have so much slack because if the fiber needs to be spliced it needs to be "unrolled" from the pole and the two ends must be brought into a special truck where a controlled environment and special equipment for fiber splicing is installed.

- All this is explained [here on Utility Industry (utilityindustry.info) website](https://utilityindustry.info/fiber-optic/). Excerpts follow (emphasized in red italics by me - boldface is in original text):

- > Whenever a splice is made in the cable, the ends have to be pulled in to a fiber trailer or other specially constructed truck in order to be spliced. Unlike phone and coax, fiber optic cable cannot be spliced at a pedestal, or at the site of a cable damage. **An optical cable must be spliced in an environmentally controlled room to prevent any dust or dirt particles from being on the fiber ends.** Even a single dust particle on the end of the strand can prevent the optical signal from being operational. When fiber cable is installed, either aerially or underground, additional cable is always wound up in handholes, manholes, and on power poles. It is probably the most obvious sign of optical cable in a handhole, <span class="has-color-red-800">_there is always a great deal of cable wound up inside the handhole to allow for the cable to be extended over to the fiber trailer._</span>

- >

- ><br>

- >

- > On a pole line fiber cables usually have **orange bands** attached to the cable. <span class="has-color-red-800">_Aerial fiber also has continual loops, **snow shoe loops**, and for the same reason that handholes have loops. These wind the cable back and forth from pole to pole several times, and to ensure that each bend is not too extreme, the bends are placed in the plastic housings which look a lot like snow shoes. These are extremely common on fiber optic cables on pole lines_,</span> and have a very distinctive appearance. This is not a company procedure. It is a standard with fiber cable no matter whom the owner.

- >

- ><br>

- >

- > <span class="has-color-red-800">_The abundance of fiber cable loops also allows for any fiber splice to be performed as a single splice._</span> With fiber optic cable every splice has a very negative effect, and those splices need to be kept to a bare minimum. That extra fiber cable in manholes and attached to pole lines ensures that any splice is a single splice, not two splices when only one was needed.

- <br>

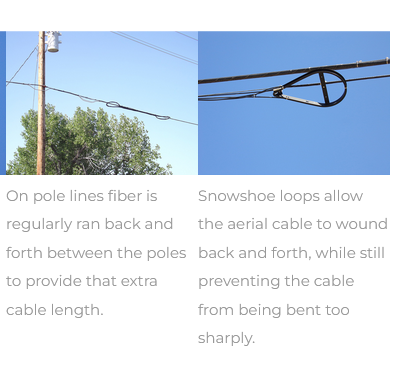

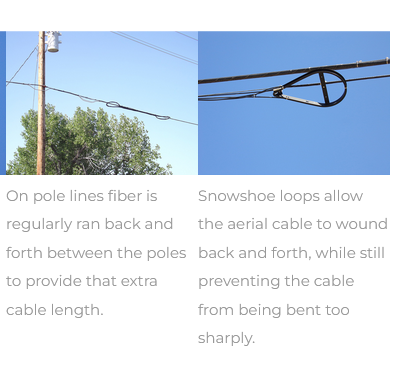

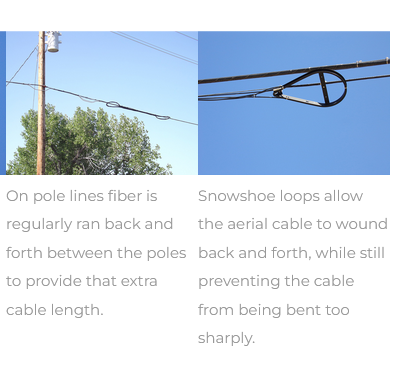

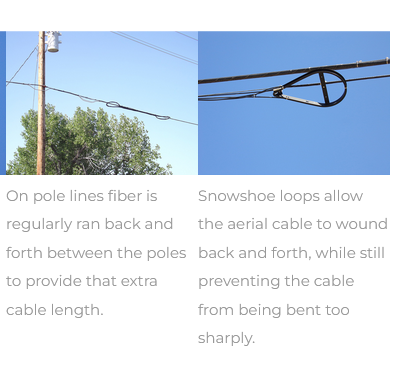

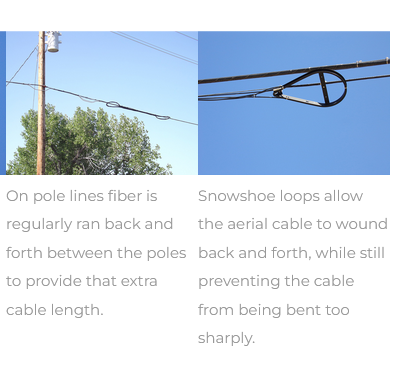

- In particular, here's a snapshot of that web page with photos that match yours:

- >

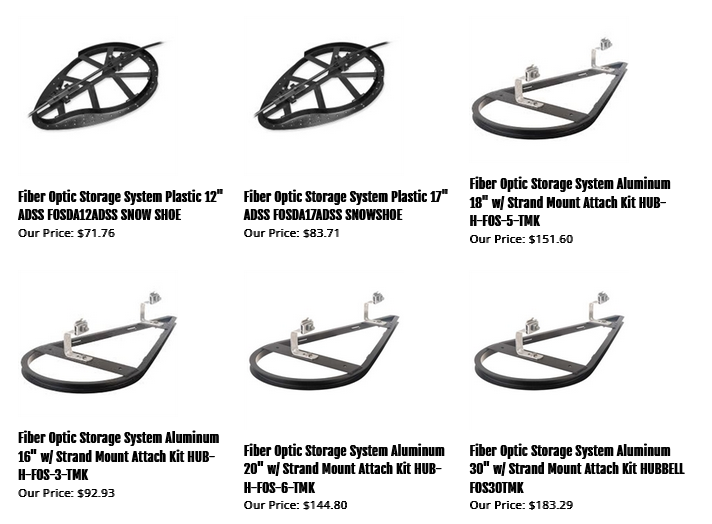

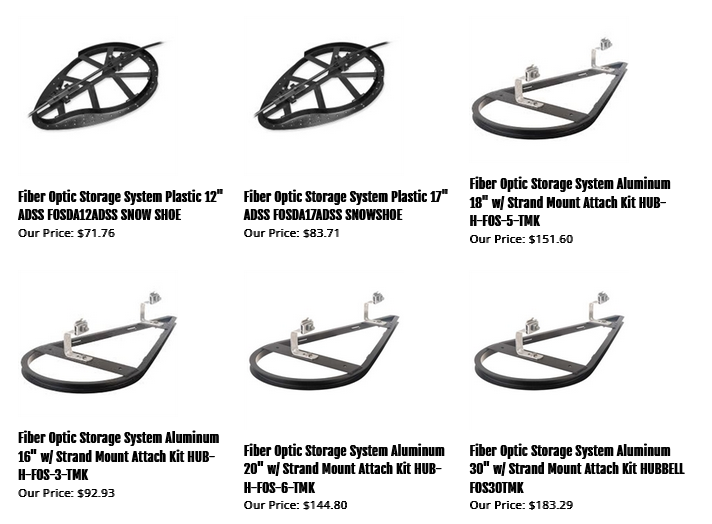

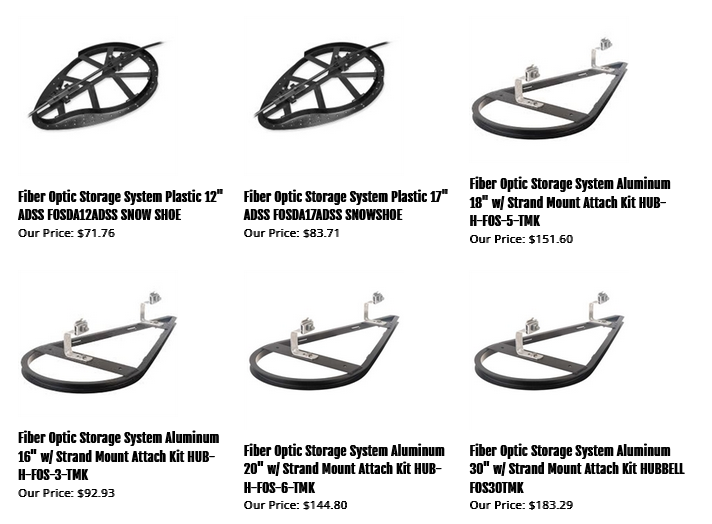

- Here is also a [website](https://www.linemen-tools.com/Fiber_Storage_Sno_Shoes_s/530.htm) selling those snowshoes (it seems it's their actual technical name, go figure!). Here is a snapshot for reference:

- >

- [This document](https://fiber-optic-catalog.ofsoptics.com/documents/pdf/IP-003.pdf) about the installation of aerial fiber optics cables also mentions the snowshoes as a slack storage method (section 9).

- See also this document: [Lashed Aerial Installation

- of Fiber Optic Cable (Corning)](https://www.corning.com/catalog/coc/documents/standard-recommended-procedures/005-010.pdf). It briefly mentions snowshoes (and it's interesting on its own).

- Those are fiber optic cables that are wound back and forth between those "snowshoe" devices, which are used to limit the bend radius of the fiber.

- Those are needed to avoid propagation losses due to the fiber being bent more than its rated maximum bend radius.

- The fiber must have so much slack because if the fiber needs to be spliced it needs to be "unrolled" from the pole and the two ends must be brought into a special truck where a controlled environment and special equipment for fiber splicing is installed.

- All this is explained [here on Utility Industry (utilityindustry.info) website](https://utilityindustry.info/fiber-optic/). Excerpts follow (emphasized in red italics by me - boldface is in original text):

- > Whenever a splice is made in the cable, the ends have to be pulled in to a fiber trailer or other specially constructed truck in order to be spliced. Unlike phone and coax, fiber optic cable cannot be spliced at a pedestal, or at the site of a cable damage. **An optical cable must be spliced in an environmentally controlled room to prevent any dust or dirt particles from being on the fiber ends.** Even a single dust particle on the end of the strand can prevent the optical signal from being operational. When fiber cable is installed, either aerially or underground, additional cable is always wound up in handholes, manholes, and on power poles. It is probably the most obvious sign of optical cable in a handhole, <span class="has-color-red-800">_there is always a great deal of cable wound up inside the handhole to allow for the cable to be extended over to the fiber trailer._</span>

- >

- ><br>

- >

- > On a pole line fiber cables usually have **orange bands** attached to the cable. <span class="has-color-red-800">_Aerial fiber also has continual loops, **snow shoe loops**, and for the same reason that handholes have loops. These wind the cable back and forth from pole to pole several times, and to ensure that each bend is not too extreme, the bends are placed in the plastic housings which look a lot like snow shoes. These are extremely common on fiber optic cables on pole lines_,</span> and have a very distinctive appearance. This is not a company procedure. It is a standard with fiber cable no matter whom the owner.

- >

- ><br>

- >

- > <span class="has-color-red-800">_The abundance of fiber cable loops also allows for any fiber splice to be performed as a single splice._</span> With fiber optic cable every splice has a very negative effect, and those splices need to be kept to a bare minimum. That extra fiber cable in manholes and attached to pole lines ensures that any splice is a single splice, not two splices when only one was needed.

- <br>

- In particular, here's a snapshot of that web page with photos that match yours:

- >

- Here is also a [website](https://www.linemen-tools.com/Fiber_Storage_Sno_Shoes_s/530.htm) selling those snowshoes (it seems it's their actual technical name, go figure!). Here is a snapshot for reference:

- >

- [This document](https://fiber-optic-catalog.ofsoptics.com/documents/pdf/IP-003.pdf) about the installation of aerial fiber optics cables also mentions the snowshoes as a slack storage method (section 9).

- See also this document: [Lashed Aerial Installation

- of Fiber Optic Cable (Corning)](https://www.corning.com/catalog/coc/documents/standard-recommended-procedures/005-010.pdf). It briefly mentions snowshoes (and it's interesting on its own).

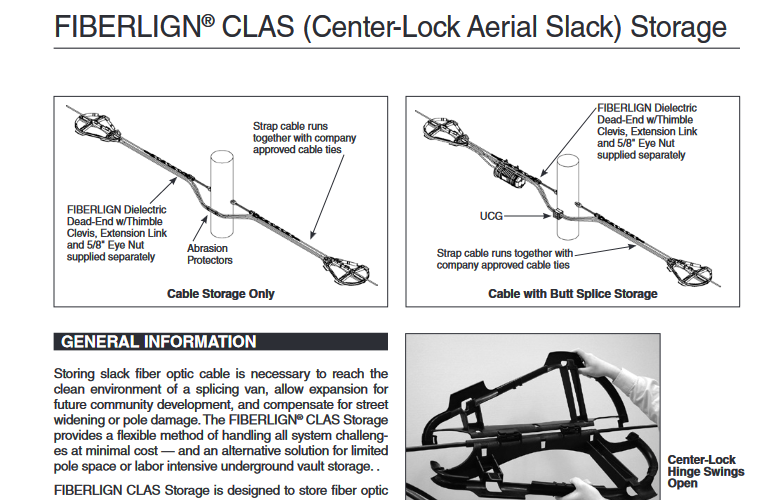

- And also this [datasheet for a fiber optics snowshoe](https://preformed.com/images/pdfs/Energy/Fiber_Optics/Cable_Storage_Systems/Fiberlign_CLAS/Fiberlign_CLAS_Center-Lock_Aerial_Slack_Storage.pdf). Excerpt:

- >

#2: Post edited

- Those are fiber optic cables that are wound back and forth between those "snowshoe" devices, which are used to limit the bend radius of the fiber.

- Those are needed to avoid propagation losses due to the fiber being bent more than its rated maximum bend radius.

- The fiber must have so much slack because if the fiber needs to be spliced it needs to be "unrolled" from the pole and the two ends must be brought into a special truck where a controlled environment and special equipment for fiber splicing is installed.

- All this is explained [here on Utility Industry (utilityindustry.info) website](https://utilityindustry.info/fiber-optic/). Excerpts follow (emphasized in red italics by me - boldface is in original text):

- > Whenever a splice is made in the cable, the ends have to be pulled in to a fiber trailer or other specially constructed truck in order to be spliced. Unlike phone and coax, fiber optic cable cannot be spliced at a pedestal, or at the site of a cable damage. **An optical cable must be spliced in an environmentally controlled room to prevent any dust or dirt particles from being on the fiber ends.** Even a single dust particle on the end of the strand can prevent the optical signal from being operational. When fiber cable is installed, either aerially or underground, additional cable is always wound up in handholes, manholes, and on power poles. It is probably the most obvious sign of optical cable in a handhole, <span class="has-color-red-800">_there is always a great deal of cable wound up inside the handhole to allow for the cable to be extended over to the fiber trailer._</span>

- >

- ><br>

- >

- > On a pole line fiber cables usually have **orange bands** attached to the cable. <span class="has-color-red-800">_Aerial fiber also has continual loops, **snow shoe loops**, and for the same reason that handholes have loops. These wind the cable back and forth from pole to pole several times, and to ensure that each bend is not too extreme, the bends are placed in the plastic housings which look a lot like snow shoes. These are extremely common on fiber optic cables on pole lines_,</span> and have a very distinctive appearance. This is not a company procedure. It is a standard with fiber cable no matter whom the owner.

- >

- ><br>

- >

- > <span class="has-color-red-800">_The abundance of fiber cable loops also allows for any fiber splice to be performed as a single splice._</span> With fiber optic cable every splice has a very negative effect, and those splices need to be kept to a bare minimum. That extra fiber cable in manholes and attached to pole lines ensures that any splice is a single splice, not two splices when only one was needed.

- <br>

- In particular, here's a snapshot of that web page with photos that match yours:

- >

- Those are fiber optic cables that are wound back and forth between those "snowshoe" devices, which are used to limit the bend radius of the fiber.

- Those are needed to avoid propagation losses due to the fiber being bent more than its rated maximum bend radius.

- The fiber must have so much slack because if the fiber needs to be spliced it needs to be "unrolled" from the pole and the two ends must be brought into a special truck where a controlled environment and special equipment for fiber splicing is installed.

- All this is explained [here on Utility Industry (utilityindustry.info) website](https://utilityindustry.info/fiber-optic/). Excerpts follow (emphasized in red italics by me - boldface is in original text):

- > Whenever a splice is made in the cable, the ends have to be pulled in to a fiber trailer or other specially constructed truck in order to be spliced. Unlike phone and coax, fiber optic cable cannot be spliced at a pedestal, or at the site of a cable damage. **An optical cable must be spliced in an environmentally controlled room to prevent any dust or dirt particles from being on the fiber ends.** Even a single dust particle on the end of the strand can prevent the optical signal from being operational. When fiber cable is installed, either aerially or underground, additional cable is always wound up in handholes, manholes, and on power poles. It is probably the most obvious sign of optical cable in a handhole, <span class="has-color-red-800">_there is always a great deal of cable wound up inside the handhole to allow for the cable to be extended over to the fiber trailer._</span>

- >

- ><br>

- >

- > On a pole line fiber cables usually have **orange bands** attached to the cable. <span class="has-color-red-800">_Aerial fiber also has continual loops, **snow shoe loops**, and for the same reason that handholes have loops. These wind the cable back and forth from pole to pole several times, and to ensure that each bend is not too extreme, the bends are placed in the plastic housings which look a lot like snow shoes. These are extremely common on fiber optic cables on pole lines_,</span> and have a very distinctive appearance. This is not a company procedure. It is a standard with fiber cable no matter whom the owner.

- >

- ><br>

- >

- > <span class="has-color-red-800">_The abundance of fiber cable loops also allows for any fiber splice to be performed as a single splice._</span> With fiber optic cable every splice has a very negative effect, and those splices need to be kept to a bare minimum. That extra fiber cable in manholes and attached to pole lines ensures that any splice is a single splice, not two splices when only one was needed.

- <br>

- In particular, here's a snapshot of that web page with photos that match yours:

- >

- Here is also a [website](https://www.linemen-tools.com/Fiber_Storage_Sno_Shoes_s/530.htm) selling those snowshoes (it seems it's their actual technical name, go figure!). Here is a snapshot for reference:

- >

- [This document](https://fiber-optic-catalog.ofsoptics.com/documents/pdf/IP-003.pdf) about the installation of aerial fiber optics cables also mentions the snowshoes as a slack storage method (section 9).

- See also this document: [Lashed Aerial Installation

- of Fiber Optic Cable (Corning)](https://www.corning.com/catalog/coc/documents/standard-recommended-procedures/005-010.pdf). It briefly mentions snowshoes (and it's interesting on its own).

#1: Initial revision

Those are fiber optic cables that are wound back and forth between those "snowshoe" devices, which are used to limit the bend radius of the fiber. Those are needed to avoid propagation losses due to the fiber being bent more than its rated maximum bend radius. The fiber must have so much slack because if the fiber needs to be spliced it needs to be "unrolled" from the pole and the two ends must be brought into a special truck where a controlled environment and special equipment for fiber splicing is installed. All this is explained [here on Utility Industry (utilityindustry.info) website](https://utilityindustry.info/fiber-optic/). Excerpts follow (emphasized in red italics by me - boldface is in original text): > Whenever a splice is made in the cable, the ends have to be pulled in to a fiber trailer or other specially constructed truck in order to be spliced. Unlike phone and coax, fiber optic cable cannot be spliced at a pedestal, or at the site of a cable damage. **An optical cable must be spliced in an environmentally controlled room to prevent any dust or dirt particles from being on the fiber ends.** Even a single dust particle on the end of the strand can prevent the optical signal from being operational. When fiber cable is installed, either aerially or underground, additional cable is always wound up in handholes, manholes, and on power poles. It is probably the most obvious sign of optical cable in a handhole, <span class="has-color-red-800">_there is always a great deal of cable wound up inside the handhole to allow for the cable to be extended over to the fiber trailer._</span> > ><br> > > On a pole line fiber cables usually have **orange bands** attached to the cable. <span class="has-color-red-800">_Aerial fiber also has continual loops, **snow shoe loops**, and for the same reason that handholes have loops. These wind the cable back and forth from pole to pole several times, and to ensure that each bend is not too extreme, the bends are placed in the plastic housings which look a lot like snow shoes. These are extremely common on fiber optic cables on pole lines_,</span> and have a very distinctive appearance. This is not a company procedure. It is a standard with fiber cable no matter whom the owner. > ><br> > > <span class="has-color-red-800">_The abundance of fiber cable loops also allows for any fiber splice to be performed as a single splice._</span> With fiber optic cable every splice has a very negative effect, and those splices need to be kept to a bare minimum. That extra fiber cable in manholes and attached to pole lines ensures that any splice is a single splice, not two splices when only one was needed. <br> In particular, here's a snapshot of that web page with photos that match yours: >