Post History

Can a circuit board be waterproof enough to form a wall of a waterproof enclosure? Regular PCBs made of FR-4 with solder mask is what I have in mind. But I'm not barring less common PCB materials...

#1: Initial revision

PCB as a wall of an underwater enclosure

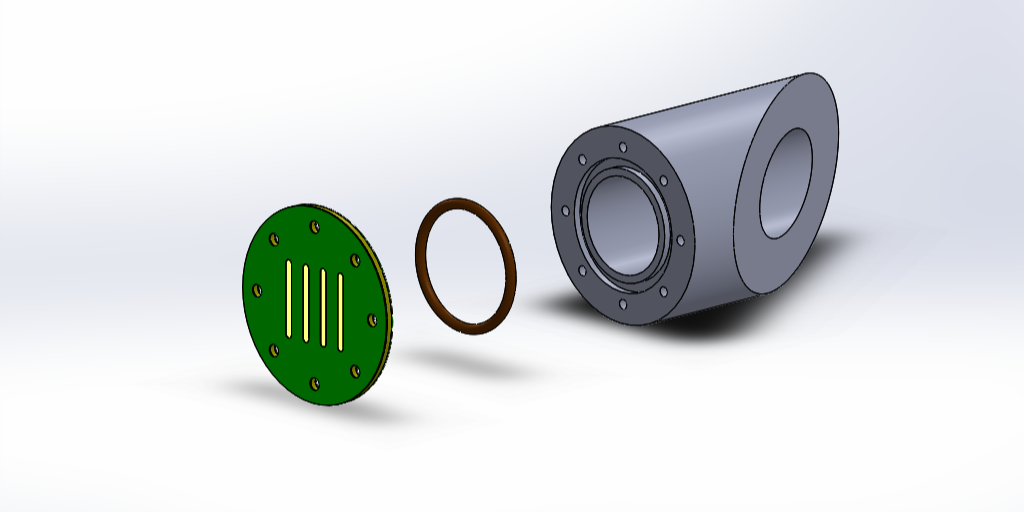

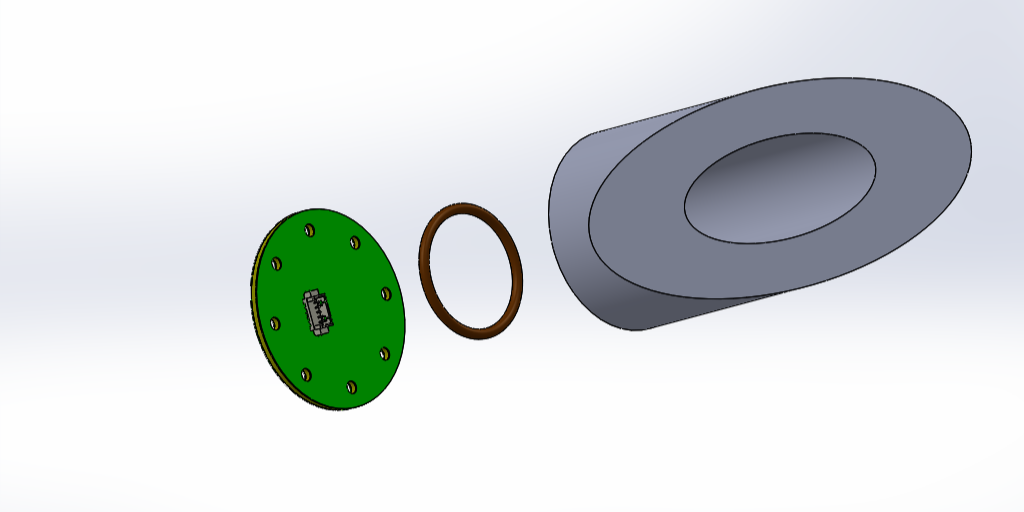

Can a circuit board be waterproof enough to form a wall of a waterproof enclosure? Regular PCBs made of FR-4 with solder mask is what I have in mind. But I'm not barring less common PCB materials and processes, although I'd prefer something with moderate cost in moderate quantities. 10m depth in river and sea water. Temperature range between +4°C and +40°C. An ability to withstand freezing temperatures isn't required. But it's desirable, because that would let me field-test the device year round where I live. Why would I want to expose a PCB to water? The malice aforethought is that the PCB has electrodes on the water side and a connector on the dry side. Here’s a rough and naïve sketch of what I have in mind.   Solder mask overlaps the edges of the electrodes, and prevents water from getting under the electrodes. Is ENIG plating enough to provide corrosion resistance for the exposed parts of the electrodes? Vias are tented (or plugged, or via-in-pad, if necessary). **My findings so far:** I asked several PCB suppliers at a trade show about waterproofing PCBs, and one of them mentioned in passing that solder mask is waterproof. The common solder mask materials are epoxies (from what I read on the web), and epoxies can make good water resistant coatings. Two layers of solder mask, if coverage defects are a concern. The [wiki about FR-4](https://en.wikipedia.org/wiki/FR-4) says that it has “near-zero water absorption”. [^1]: Ability to withstand freezing temperatures is desirable, because that would let me field-test the device year round where I live.